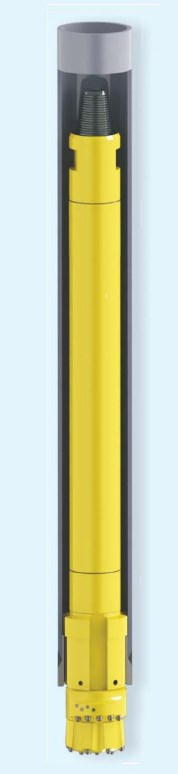

Eccentric drilling tools with casing tube are very popular in international water well and ore drilling. It is a downhole air hammer system designed to advance casing during drilling. Once the desired depth is reached, the eccentric bit can be removed, leaving the casing in place for sampling or installation. After drilling is complete, remove the casing for reuse.

Eccentric casing drilling bits are today's preferred method of drilling in difficult surface conditions, such as where there are boulders or loose formations. The overburden casing drilling bits is the most economical solution as its clever wing bit is retractable for the next hole. This is especially suitable for shallow holes, which is often the case in water well drilling, geothermal wells and shallow micro-piling work. EDS is ideal for consolidating short holes in overlays.

Our eccentric overburden casing drilling bits are sold all over the world. Main markets: Brazil, Chile, Colombia, Uruguay, Australia, Ukraine, Russia, Norway, Turkey, the United States, Canada, Iran, Malaysia, Thailand, India, etc.

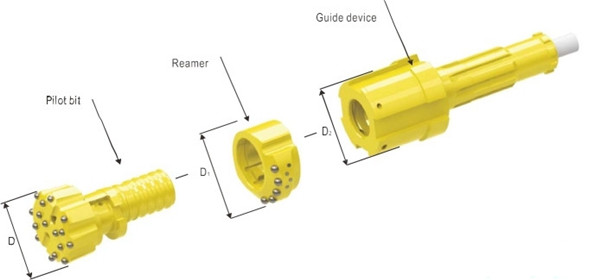

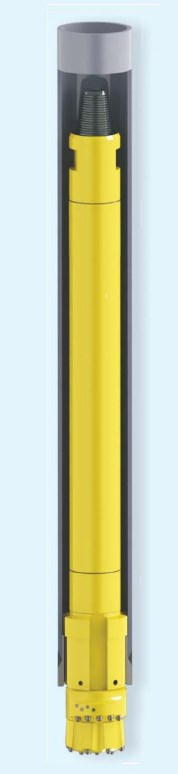

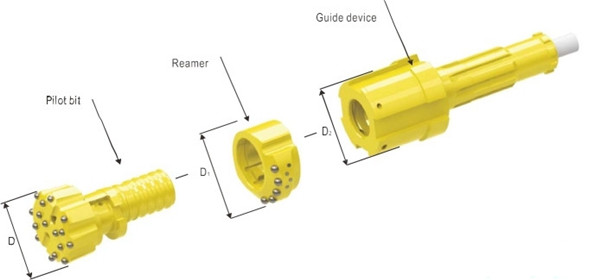

The component of eccentric system consists of pilot bits, reamer bits, guide device and casing shoe.

Working principle of eccentric drilling tool with casing:

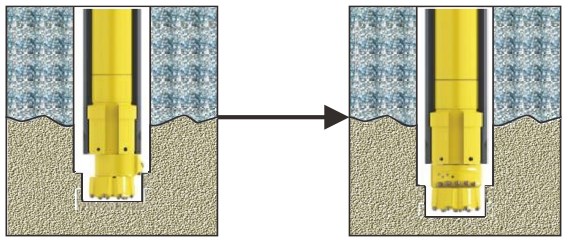

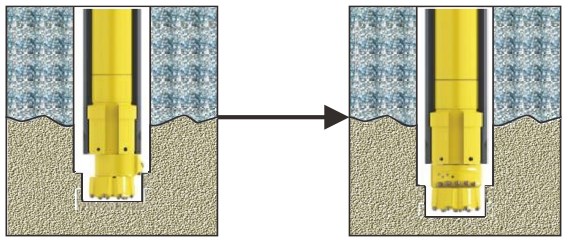

When drilling, the reaming drill bits rotate outward, widening the hole enough for the casing to slide down behind the reamer. When the desired depth is reached, the drill pipe will reverse the hole and the reamer bit will retract, allowing the entire drilling system to pass through the casing.

Eccentric drilling tools with casing tube step-by-step:

1. When drilling, the PGZ reamer swings out and drills a hole wide enough for the casing tube to slide down behind the reamer.

2. When required depth is reached, the drill is reversed and the reamer swings in, allowing the bit to pass through the casing.

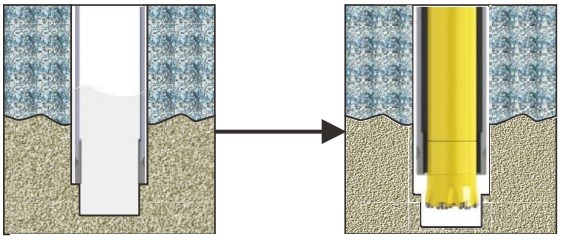

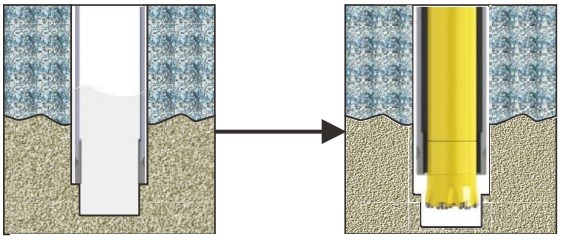

3. Casing tube is pulled out directly or fixed atthe bottom of the hole by means of cement grout or other agglutinant.

4. Drilling continues to the desired depth using conventional DTH equipment.