1. The lightweight concrete making equipment adopts containerized structure, which is easy to install and move and transport, and the GF30A high-pressure type lightweight concrete work plantcan be transported with a 4.2-meter truck;

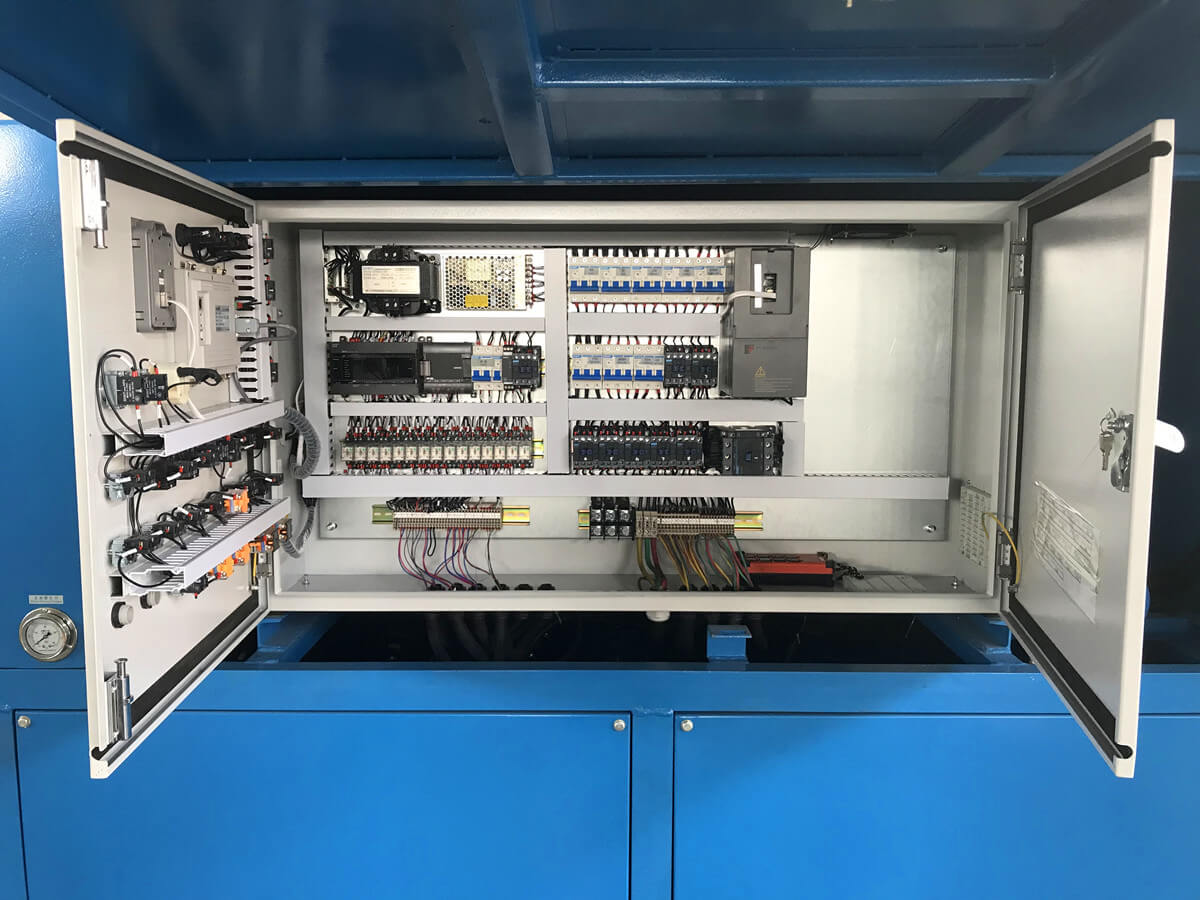

2. Pouring lightweight concrete plant is equipped with lightweight concrete density monitoring and control device, adopting touch screen intelligent control system, the working status of the equipment and various parameters are intuitively displayed on the screen, which is convenient for the judgment of the working status and centralized control;

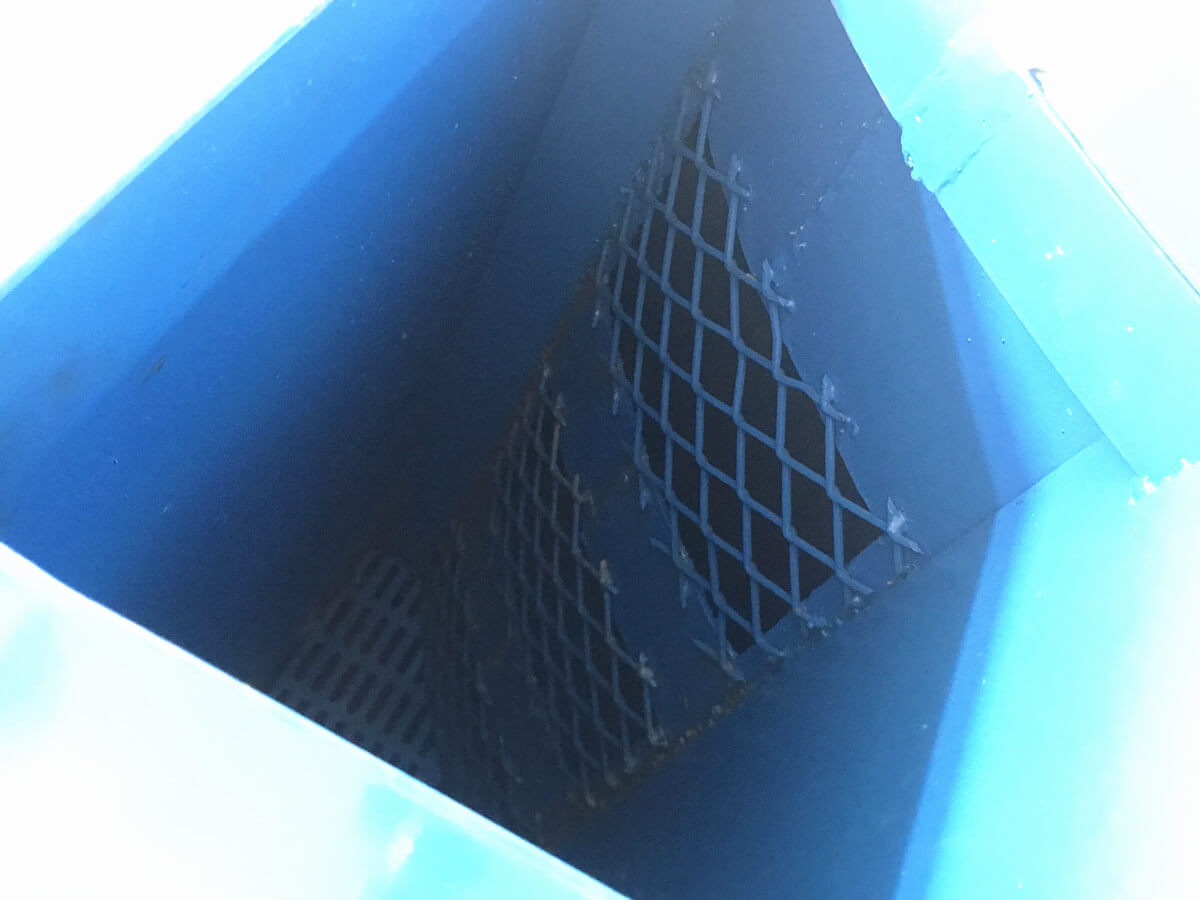

3. Powder metering, slurry mixing, and slurry storage are divided into a three-tier structure, which can be added or subtracted in combination as needed;

4. Standard with material batching and measuring device, cement, powder, water, etc. can be measured separately, accurate control of material ratios;

5. Backfill lightweight concrete plant is equipped with daily production report output interface or printing device as standard, which can summarize and output or print the daily consumption of cement, fly ash, foaming agent and other materials as well as the output of lightweight concrete;

6. Full-automatic control, equipped with lightweight concrete density monitoring and control device, the equipment can automatically adjust the ratio of materials at the front end according to the density data detected, so that the density of the lightweight concrete produced meets the set requirements.