GCPM Hydraulic discharging concrete planetary mixer features:

1. Embracing a distinctive modular architecture, our mixer stands out for its ease of disassembly and reassembly. This flexibility makes it an ideal fit for diverse settings, ranging from batching plants to concrete precast component facilities.

2. Our firm has pioneered an exceptional mixing mechanism: employing aerodynamic mixing arms that effectively thwart material adhesion to the shaft. The mixing blade, ingeniously shaped as a parallelogram, can be rotated 180 degrees for dual usage. This innovation at least doubles the blade's service life, maximizing resource utilization.

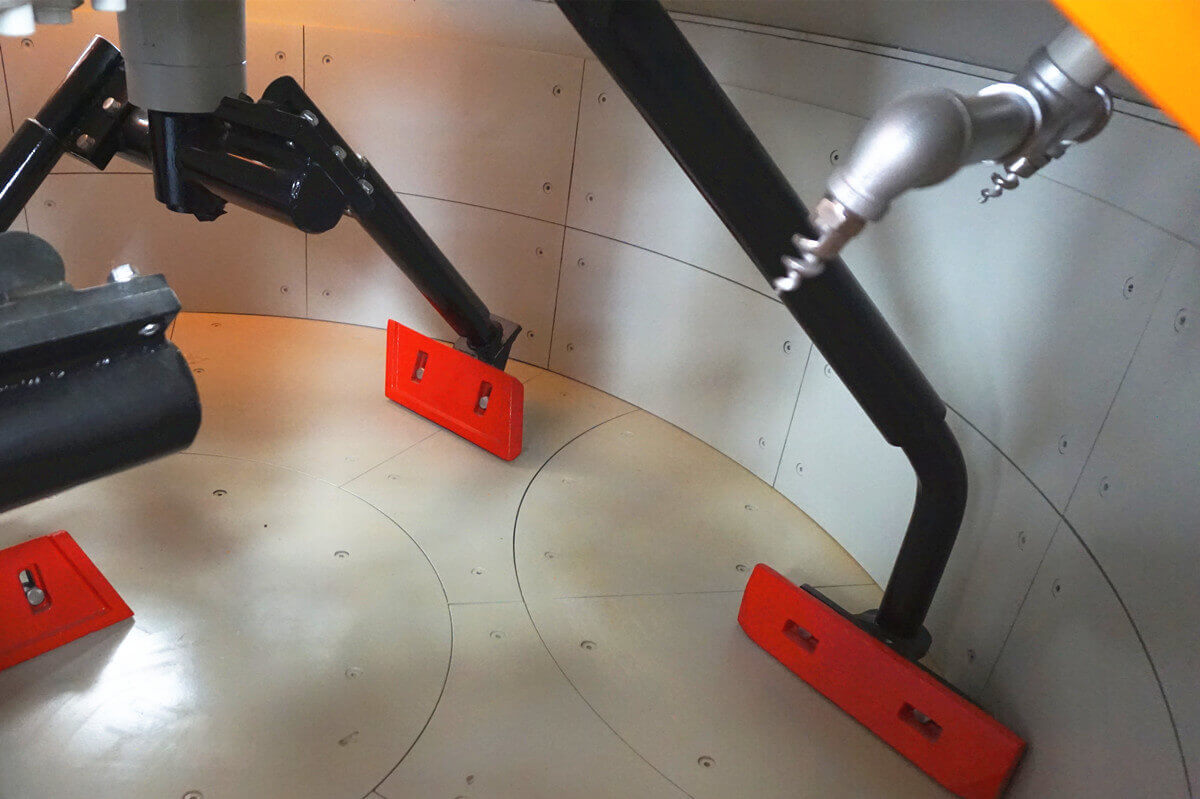

3. The hydraulic discharging concrete planetary mixer's wear-prone components, including the shaft-end seals, liner plates, mixing arms, and blades, are fortified with wear-resistant materials. This strategic choice minimizes downtime for maintenance and bolsters operational efficiency.

4. The planetary concrete mixer with hydraulic discharging door is encapsulated in a fully-sealed enclosure, which proficiently averts slurry leakage and mitigates environmental contamination, ensuring a cleaner workspace.

5. With the capability to concurrently activate up to three discharge doors, the mixer accelerates the workflow, shaving off precious minutes from the production cycle.

6. We have engineered our proprietary reducer, distinguished by its rational speed configuration and virtually silent operation. Its high reliability and straightforward maintenance contribute to its outstanding performance.

7. Committed to unparalleled customer support, we are able to quickly resolve any questions or concerns, and professional engineers are on call to provide timely assistance 24/7 to ensure your peace of mind and business continuity.

GCPM Hydraulic discharging concrete planetary mixer details:

| Emergency switch |

Hydraulic power unit |

|

|

| Maintaining door |

Mixing device |

|

|

| Observing port |

Water spray pipe |

|

|