1. Superior Blending Capabilities

Featuring a reverse rotation of the mixing elements against the drum's revolution, each component follows a distinct path. This dual circulation and convective motion induce rigorous mixing. The counter-current action and material impact prevent clumping, ensuring microscopic uniformity and thorough blending.

2. Enhanced Mixing Velocity, Reduced Power Consumption

Innovative refractory planetary mixer design engenders a complex mixing trajectory, achieving intense blending and optimal outcomes. Under identical circumstances, the mixing duration is shortened by 15-20% compared to conventional planetary mixers. An advanced power and gear system boasts greater transmission efficiency. The re-engineered mixing apparatus yields superior results, with unloaded and loaded currents (for equivalent materials) diminished by 15-20% relative to traditional planetary concrete mixers.

3. Customizable Rotational Speed Settings

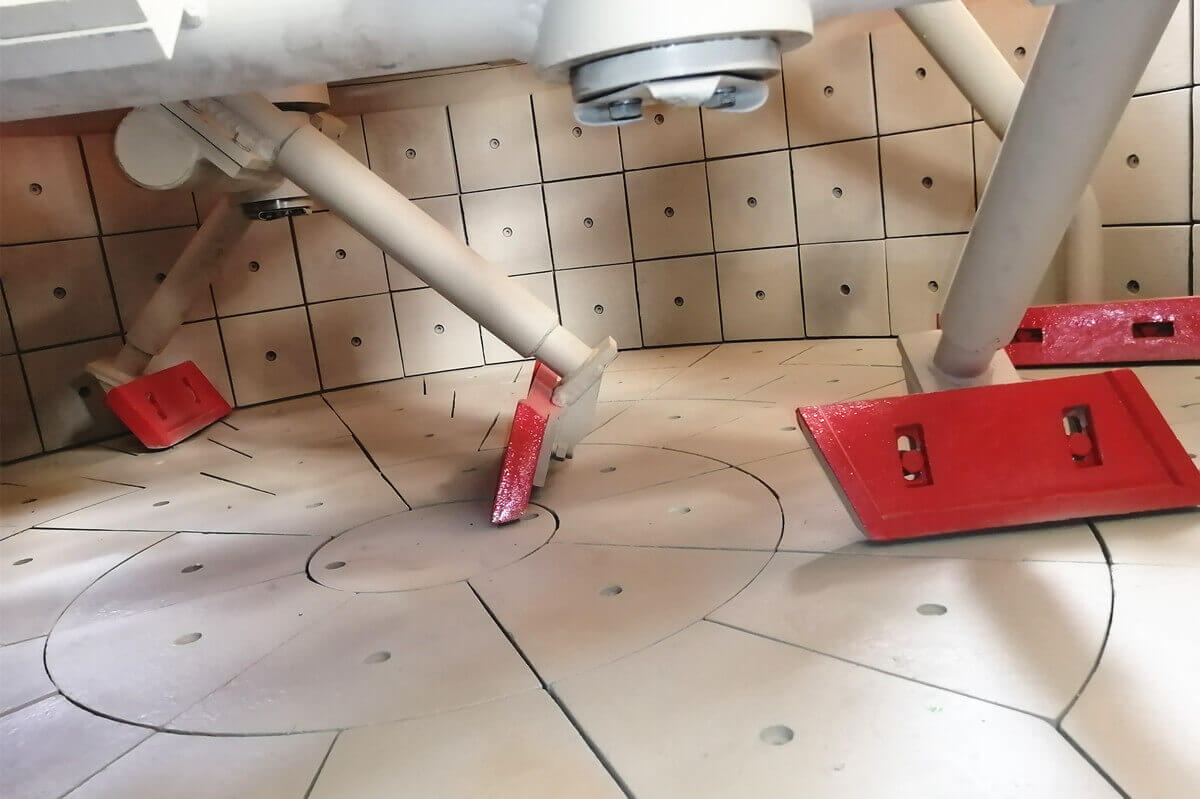

4. Optimized Mixing Device Configuration

Refined dimensions, angles, and shapes of the mixing blades, coupled with enhanced arm structures, facilitate efficient blending, balanced gear system load distribution, and expedient, complete material discharge.

5. Advanced Cover Redesign

A spacious upper aperture in the cover facilitates direct gearbox removal without dismantling feeding mechanisms, significantly enhancing maintenance accessibility. The enlarged maintenance hatch eases personnel entry and wear-part replacement. Enhanced cover sealing enhances dust exclusion.

6. Hydraulic Discharge Door & Pneumatic Discharge Door

According to the different demands of customers, the discharging door can be opened by hydraulic, pneumatic, or by hand. The number of the discharging door is three at most. And there is a special sealing device on the discharging door to ensure the sealing is reliable.

7. Safety-Focused Design

An emergency stop button, activated via key, halts mixer operations instantly in crises. Key removal during maintenance ensures safety. An inspection window on the maintenance hatch permits monitoring of the mixing process while the mixer is in operation. A high-reliability, sensitive safety switch on the maintenance hatch prevents motor activation when the hatch is open.

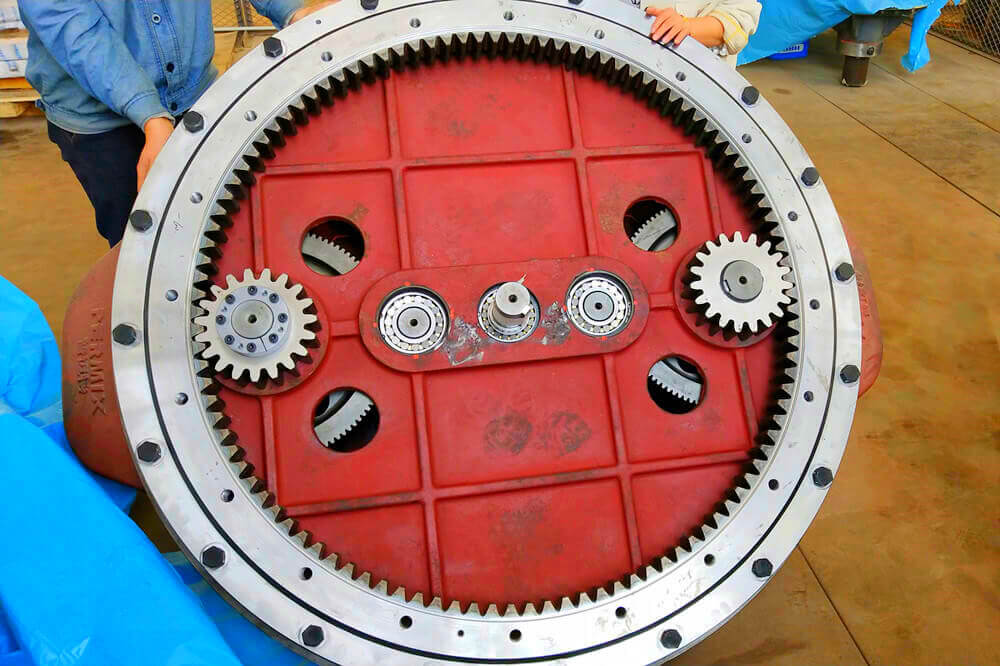

8. Unmatched Gearbox System

The newly engineered, compact gearbox is more robust and enduring. Its size is 30% less voluminous than that of MP planetary mixers, providing ample servicing room within the trough. Upgraded shaft sealing and an electric grease pump extend gearbox lifespan and minimize upkeep.

Details pictures of GCPM Counter current planetary concrete mixer with lift skip hoist and hopper:

| Butterfly valve |

Dust remove system |

|

|

| Gearing system |

Mixing system |

|

|

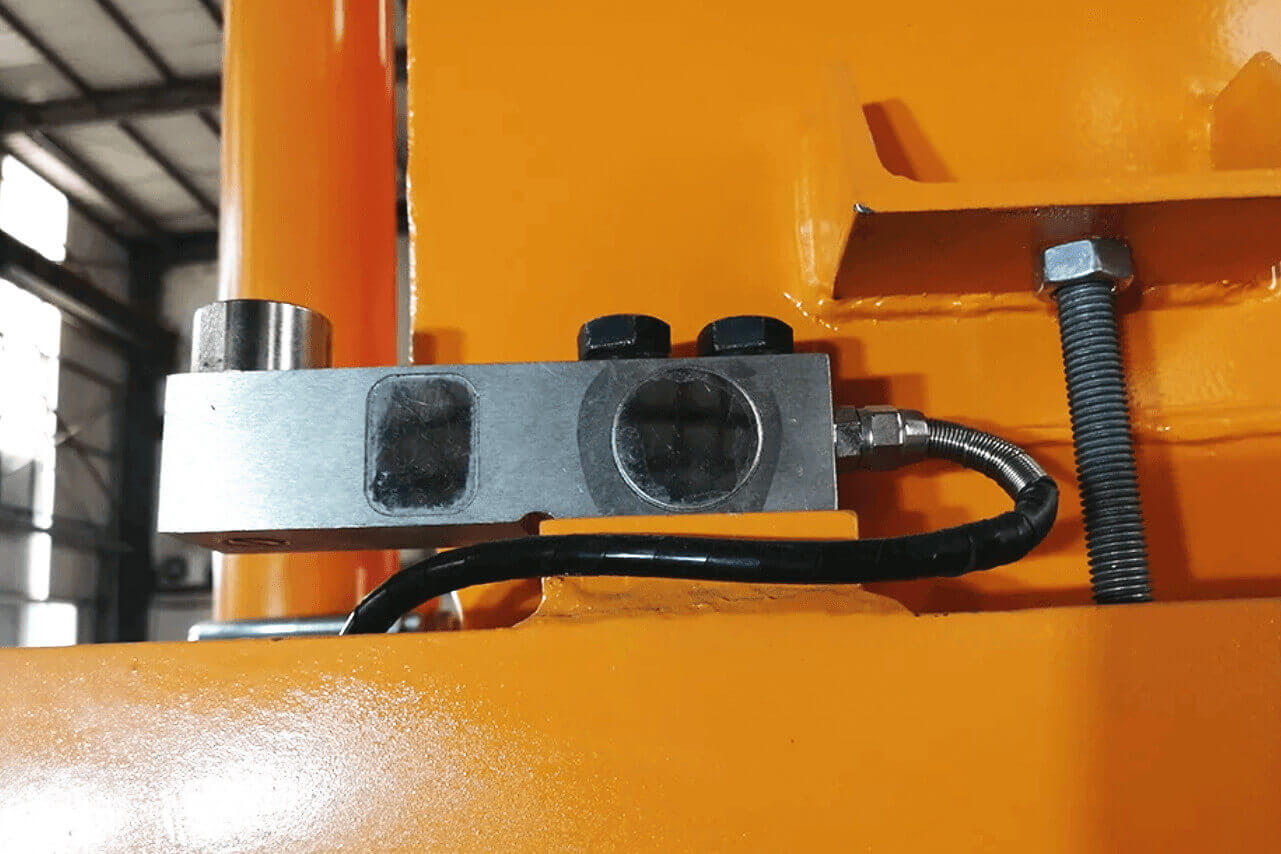

| Weighing sensor |

Water dosing system |

|

|