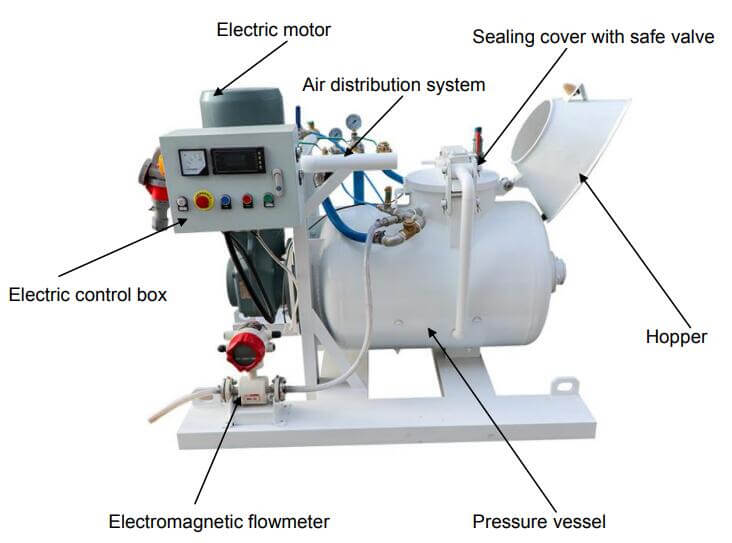

GDPX series refractory mixing and conveying unit is specially designed for conveying of solid and moistened mortar, concrete mixture and refractory castable. It is suitable for the using in the metallurgical industry produce permanent linings for ladles, tundish, blast furnace runners, on industrial and melting furnaces for the glass and aluminium industry. The pneumatic refractory mixing and conveying unit can be used also in the building (construction) industry at the concreting of base of building, floors and larger concreted areas.

Working principle of refractory mixing and pressure conveying unit:

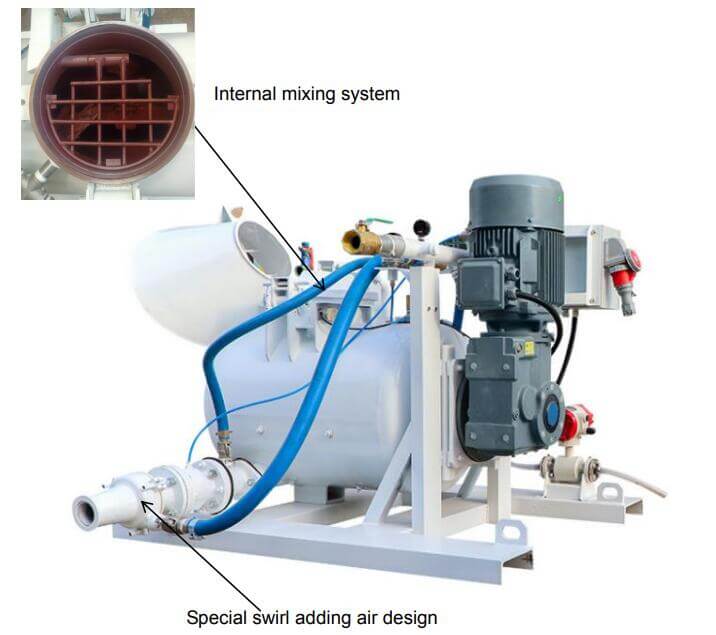

Mixture closed in the pressure tank will be mixed by motion of mixing blades and by the compressed air. Mixing blades slide simultaneously the mixture and push it into the discharge port of the tank. Additional, lower position compressed air entering into the conveying hose and blow mixture uniform motion of in transport hoses. Transport of the mixture in the conveying hose passes in agglomerates, and unique swirling air path design makes the materials will not produce large fluctuations.