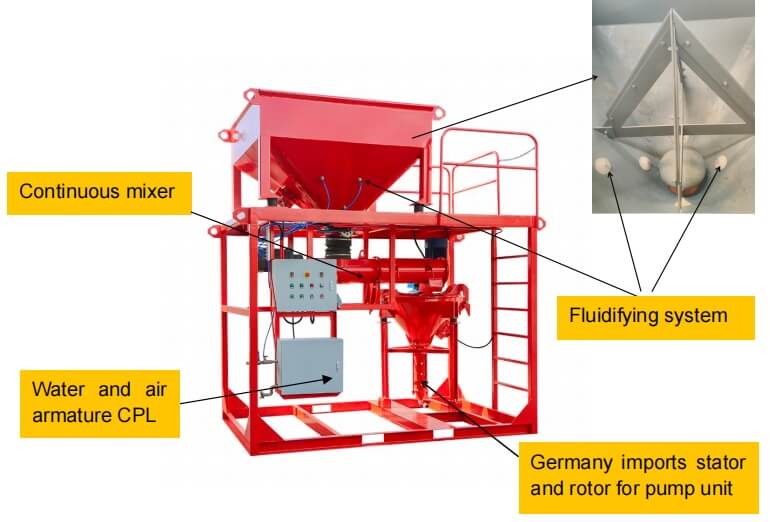

Product features of GTS-40E/S Tundish spraying machine:

1. Frame

A steel frame with ladder, platform and rails detachable for transport herein included

2. 1500L Hopper

Dry mortar hopper with BIG-BAG-cutter detachable for transport

BIG-BAG cutter

Fluidifying system on dry mortar silo with compressed air control

OLI Vibrator for dry mortar refractory hopper

3. Continuous Mixer

Transferring and stirring 2 parts

The mixing blade is made of wear-resistant steel and, which can easily replace the blade.

GEKA quick connector (water filling port)

4. Pump Unit

Hopper with vibrator

Vertical mortar screw pump

Germany imports stator and rotor

Level probe for wet mortar hopper (Optional part)

5. Control System (safe, and easy to operate)

6. Water and Air Armature CPL

Air control :

Water control: for continuous mixer

7. 350L Water Tank (optional part)

304 stainless steel water tank

A heating and pressurization system

GEKA quick connector

Product advantages of GTS-40E/S Tundish liner spraying machine:

★ Always homogenous mix by steadily working continuous mixer;

★ Adjustable, controlled water-material proportion;

★ Constant conveying of wet material;

★ Long lifetime by adjustable pressure and in case of wear adjustable screw pump;

★ Few wearing parts and low wear because of the use of high quality materials;

★ No dust rising during spraying;

★ Fast and easy cleaning of all machine parts that have been in contact with wet mortar refractory;

★ Joint free, monolithic coating of Tundish linings;

★ Safe and easy working conditions.