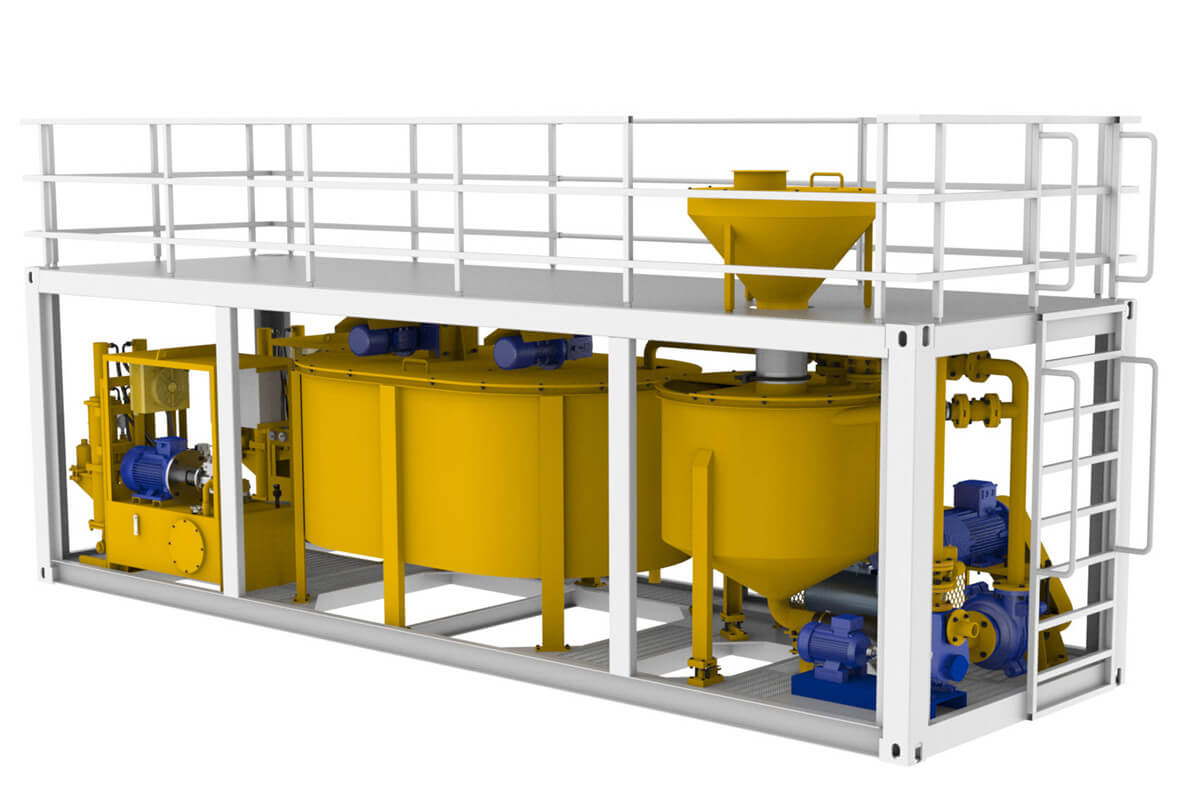

40GP container type grout mixing plant

2024-08-09 18:20:14

40GP container type grout mixing plant is an efficient and convenient mixing equipment. It uses a standard 40-foot (GP) container as the main structure, integrating multiple functions such as mixing, conveying, and storage. It is particularly suitable for engineering projects that require rapid deployment and flexible movement.

Pumping system:

Output and pressure can be step-less adjusted, pressure: 0-3MPa, flow: 2×(0-10m³/h)

Mixing system:

1000L High-speed colloidal grout mixer with a mixing shaft to the bottom. Ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid component. Cement can be added by screw feeder automatically

Storage system:

The 4000L storage tank will always have fresh grout. Make sure there is continuous grout to be supplied on site. There is also a mixing device in the storage tank to ensure the cement and water mix well.

1. Standardized design: Based on the standard size design of the 40GP container, it is easy to transport and install, while ensuring the stability and durability of the equipment.

2. Integrated design: The mixing host, metering system, conveying system, storage system, etc. are integrated in one container, which reduces the floor space and improves space utilization.

3. High degree of automation: The advanced control system is adopted to realize functions such as automatic metering, automatic mixing, and automatic conveying, which reduces the difficulty and labor intensity of manual operation.

4. Strong flexibility: It can be customized according to engineering requirements to meet the mixing needs of different projects. At the same time, the equipment can be quickly disassembled and assembled, which is convenient for transfer between different construction sites.

5. Environmental protection and energy saving: The low-noise and low-emission design is adopted to meet environmental protection requirements. At the same time, energy consumption and costs are reduced by optimizing the mixing process and energy-saving technology.

The 40GP containerized grouting and mixing plant is widely used in grouting construction in engineering fields such as tunnels, subways, bridges, water conservancy, and construction. It is particularly suitable for engineering projects that require rapid deployment and flexible movement, such as urban subway construction, tunnel lining construction, etc.

In summary, the 40GP containerized grouting and mixing plant is an efficient and convenient mixing equipment with the characteristics of standardized design, integrated design, high degree of automation, strong flexibility, and environmental protection and energy saving. Any need our 40GP container type grout mixing plant, please contact us, email address: info@gaodetec.com